NexGen Mill Column – CNC Ready

NOTE: This column is only compatible with mill XY bases, for lathe columns please click here

-

Travel, “Z” Axis: 9.38″ (238 mm)

Throat (no spacer): Adjustable

Throat (w/ headstock spacer): Adjustable

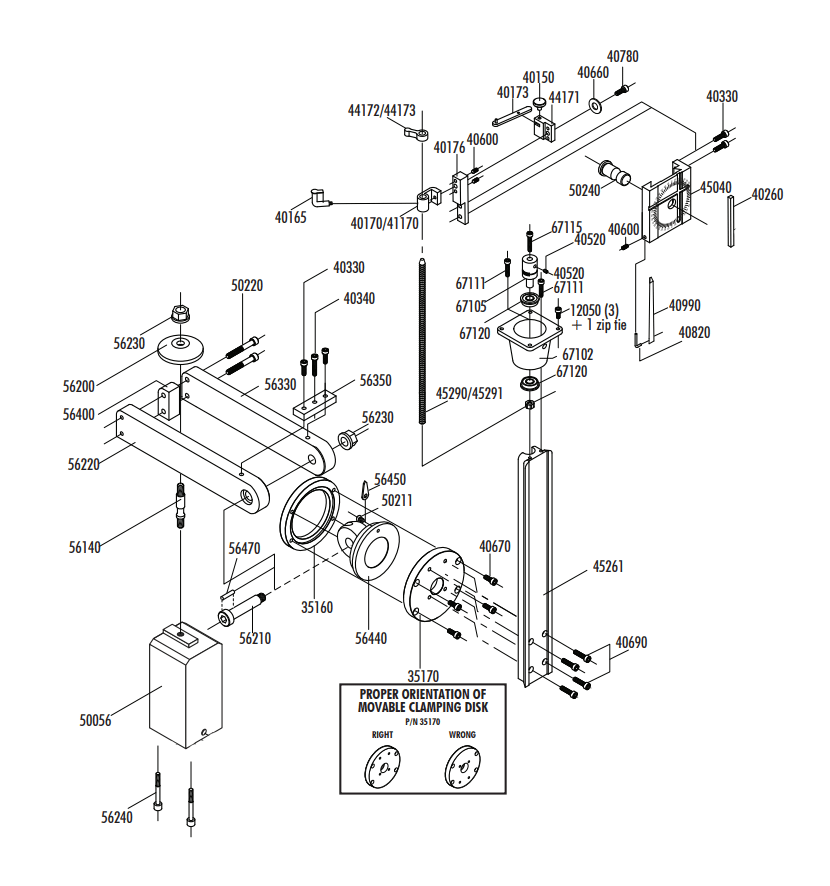

| Part No. | Description | Quantity |

|---|---|---|

| 12050 | 8-32 x 3/8″ SHCS | 3 |

| 3455 3459 | 2.5″ Z Axis Zero Adjustable Handwheel (Inch) 2.5″ Z Axis Zero Adjustable Handwheel (Metric) | 1 |

| 35160 | Graduated Clamping Ring | 1 |

| 35170 | Movable Clamp Disk | 1 |

| 4017ZOL 4117ZOL | Z-Axis Backlash Adjustment Upgrade (Inch) Z-Axis Backlash Adjustment Upgrade (Metric) | 1 |

| 40176 | Saddle Travel Extension w/Screws | 1 |

| 40260 | Head Key | 1 |

| 40330 | 10-32 x 5/8″ SHCS | 4 |

| 40340 | 10-32 x 1″ SHCS | 1 |

| 40600 | 10-32 x 1/4″ Flat Point Set Screw | 1 |

| 40660 | #10 Washer 3/16″ | 1 |

| 40670 | 10-32 x 1/2″ SHCS | 4 |

| 40690 | 10-32 x 3/4″ SHCS | 4 |

| 40740 | 10-32 x 7/8″ SHCS | 1 |

| 40820 | Gib Lock | 1 |

| 40900 | 10-32 x 3/8″ Flat Head Screw | 1 |

| 40990 | Saddle Gib | 1 |

| 45040 | Column Saddle | 1 |

| 45200 | Bored Column Thrust | 1 |

| 45261 | 15″ CNC Mill Column | 1 |

| 45290 45291 | 15″ Column Leadscrew (Inch) 15″ Column Leadscrew (Metric) | 1 |

| 50056 | Tall Rigid Square Mill Column Base | 1 |

| 50211 | 8-32 x 1/4″ Button Socket Screw | 1 |

| 50220 | 1/4-20 x 1-3/4″ SHCS | 4 |

| 50240 | Pivot Pin | 1 |

| 56130 | Arm Hold Down Bolt | 1 |

| 56200 | Arm Hold Down Washer | 1 |

| 56210 | 3/8-16 x 2″ Should Bolt | 1 |

| 56220 | Swing Arm – Left Side | 1 |

| 56230 | 3/8-16 Flange Nut | 2 |

| 56330 | Swing Arm – Right Side | 1 |

| 56350 | Column Adjustment Block | 1 |

| 56400 | Arm Spacer Block | 1 |

| 56440 | Arm Mount | 1 |

| 56450 | Index Tab | 1 |

| 56470 | 3/32″ x 1/2″ Dowel Pin | 1 |

| 67102 | Stepper Motor Mount | 1 |

| 67104 | CNC Preload Nut – Right Hand | 1 |

| 671052 | CNC Coupling | 1 |

| 67111 | 8-32 x 7/8″ SHCS | 2 |

| 67115 | 5-40 x 7/8″ SHCS | 1 |

| 67120 | Stepper Motor Preload Bearing | 2 |

| 76140 | 5/64″ Hex Key | 1 |

Related products

Stepper Motor

Sherline stepper motors feature shafts at both ends, allowing for manual control via a handwheel, if desired. Flats are ground onto each shaft to accommodate set screws for the handwheel and coupling. For use with a Sherline motor mount, ensure that the shaft entering the coupling has a flat machined or ground onto it where the set screw secures it. Failure to do so may damage the shaft, making the coupling difficult to remove. For non-Sherline applications, the flat may not be necessary.

Powerful Dual-Shaft Motors

P/N 67127: This motor comes pre-wired with six leads in a connector that plugs directly into Sherline's linear or rotary controllers. Both our CNC system and driver box include four pre-wired cables with 5-pin plugs that match the P/N 67127 stepper motor. Simply plug each stepper motor into the corresponding axis cable for an easy setup.

P/N 67130: This motor features six raw wire leads, and does not include a connector, so that it can be used with non-Sherline controllers that have a different pin configuration.

Note: Due to the lack of standardization in the industry, wire colors can vary between suppliers. If using a connector not supplied by Sherline we recommend using a continuity checker to identify which wire connects to each pin on the DIN plug. Typically, the black and white (or tan) wires are connected to the center pins, but other colors may vary. See our specifications sheet for wiring diagram.