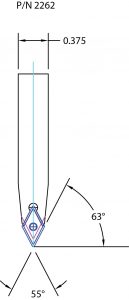

Straight Insert Tool Holder w/55° insert

This holder features a centered design (not offset to either side) and includes a 55° carbide insert, a hold-down screw, and a Torx key for installation. It has a 3/8″ square shank that fits standard 3/8″ tool posts. The straight tip design allows for general-purpose turning operations in either direction. The cutting tip is positioned 0.375″ from the bottom of the holder, which conforms to industry standards. The holder is constructed from case-hardened steel and finished with black oxide for enhanced durability and corrosion resistance.

Though more costly than traditional tools, each insert offers two usable cutting edges. When one edge becomes dull or chipped, simply rotate the insert 180° to access a new cutting surface—essentially providing two tools in one.

About the Carbide Inserts

While high-speed steel (HSS) tools remain the primary choice for miniature machine work due to their affordability and ease of resharpening, inserted-tip carbide tools offer significant advantages in specific applications. Carbide inserts excel in cutting harder materials, improving efficiency and tool life—making them invaluable in many professional machining environments.

Safety Note

Carbide inserts can produce extremely hot chips and may shatter under stress. Always wear appropriate eye protection and safety gear when using these tools.

Certain materials, such as tool steel, may form long, continuous chips that can wrap around the workpiece like steel wool. To minimize this, use a chip brush frequently or pause machining to remove chip buildup. These “bird’s nests” can ignite from hot chips, so maintain a clean workspace near the cutter.

-

| Insert Holder Material | Case Hardened Steel |

|---|---|

| Body Coating | Black Oxide |

Related products

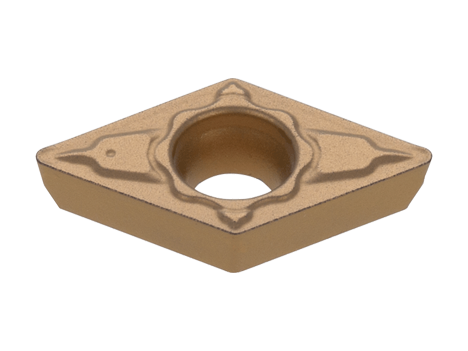

55° Carbide Insert

While not inexpensive, carbide inserts offer excellent value—each insert provides four cutting edges, significantly reducing the need for frequent sharpening and saving valuable time.

Carbide cutters perform well on hard-to-machine materials like cold-rolled steel and are also effective on aluminum, brass, and leaded steels, offering exceptional durability. However, for the finest finishes on softer metals, a well-sharpened high-speed steel tool still delivers superior results.

This is the 10-pack of replacement carbide inserts for the following tool holders:

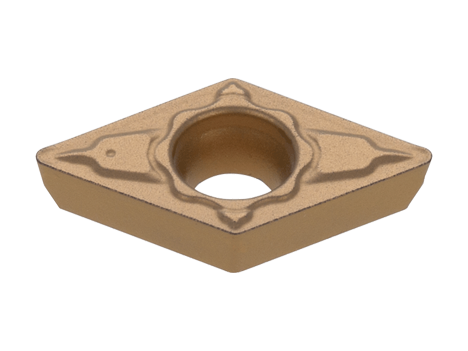

55° Carbide Insert-10 Pack

While not inexpensive, carbide inserts offer excellent value—each insert provides four cutting edges, significantly reducing the need for frequent sharpening and saving valuable time.

Carbide cutters perform well on hard-to-machine materials like cold-rolled steel and are also effective on aluminum, brass, and leaded steels, offering exceptional durability. However, for the finest finishes on softer metals, a well-sharpened high-speed steel tool still delivers superior results.

This is the 10-pack of replacement carbide inserts for the following tool holders:

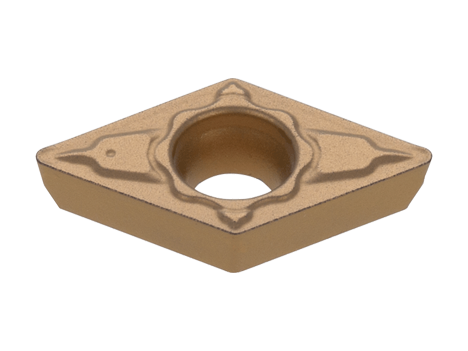

55° RH and LH Tool Holders w/Carbide Inserts

These tool holders are available individually in right-hand or left-hand configurations, or as a matched pair. Each holder includes a 55° carbide insert, a hold-down screw, and a Torx® key for installation. Designed with a 3/8" square shank, they fit standard 3/8" tool posts, and the insert tip is precisely 0.375" from the base of the holder—an industry-standard dimension.

The 5° offset angle of the cutting tip provides added versatility for certain operations. For example, when the holder is squared with the crosslide, it allows you to turn an outside diameter (O.D.) up to a shoulder and then finish the shoulder by backing the tool out—while maintaining proper tool clearance.

Constructed from case-hardened steel with a durable black oxide finish, these holders are built for long-lasting performance.

Although carbide insert tools are more costly than high-speed steel (HSS) tools, they offer an advantage: when the cutting edge becomes dull or chipped, you can simply rotate the insert 180° to use the second edge—essentially giving you two tools in one.

While HSS tools remain the primary choice for miniature machining due to their low cost, resharpenability, and adaptability for custom form tools, carbide insert tools are invaluable for specific applications. They maintain a sharp edge when cutting hard or abrasive materials, reduce tool wear, and allow for faster machining—reasons why they're widely used in professional machine shops.

Note: Tool orientation is named by the direction the chip exits the tool. A right-hand tool has its cutting edge on the left, and the chip peels off to the right.

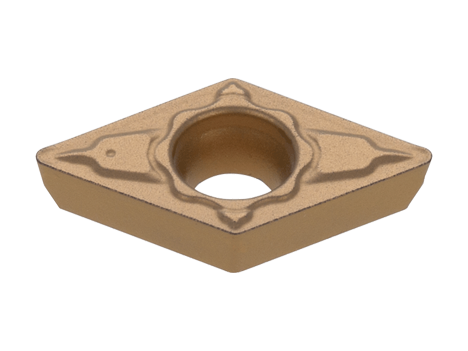

Updated Note: The previously used straight-groove chip breaker insert shown in some images is no longer available. All current inserts now come with the spider web-style chip breaker as shown here.