Product Description

Ultimate Machine Shop Package with NexGen Mill

If you want to set up a complete miniature machine shop with just one purchase, the “Ultimate Machine Shop” package makes it easy. We have combined our Model 4400/4410 deluxe benchtop lathe (3.5 x 17″) and a Model 5800/5810 NexGen benchtop vertical milling machine with many of the most popular machining accessories. Included are all the items you need to set up for most machining jobs, including cutting tools and holding fixtures.

See the individual pages in the “LATHES” and “MILLS” sections for more details on the machines and what comes with them. The package includes everything shown in the photo above.

LATHE

- 3.1″ 3-jaw Self-centering Chuck

- 3/8″ Drill Chuck w/ Arbors, Key and Drawbolt

- Steady Rest

- Live Center

- Rear Mount Cutoff Tool and Holder

- 3-pc. 1/4″ HSS Tool Set (LH, RH, Boring)

MILL

- Headstock Spacer Block

- 3 pc. Center Drill Set

- Fly Cutter w/ 1/4″ Carbide Cutting Tool

- Boring Head

- Boring Tool (5/16″ min. hole, 1″ max. depth)

- 3-pc. Mill Collet Set w/ Drawbolt

- 1/4″ Drill Chuck w/ #1 Morse Arbor, Key and Drawbolt

- 3/8″ End Mill Holder

- 6-pc. 3/8″ Shank End Mill Set

- Milling Vise

- Step Block Hold-down Set

- 4″ Rotary Table

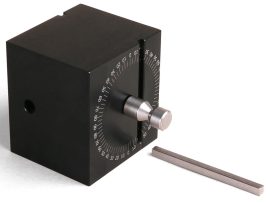

- Tilting Angle Table

MISCELLANEOUS

- 5/32″ Sherline Hex T-Driver

- Sherline Accessories Shop Guide book

- Safety Glasses