The improper use of machine tools and their accessories can result in serious injury. Before using this tool, thoroughly read the instructions and make sure you understand its proper and safe use.

CNC Linear Controller – X/Y-Axis Upgrade

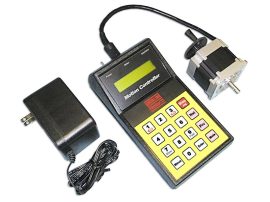

This kit upgrades the X- or Y-axis of a manual Sherline milling machine or the crosslide of a Sherline lathe for use with a CNC linear controller. It includes a CNC linear controller and all the components required to convert a manual axis to CNC operation. The linear controller comes with a stepper motor mount for machines that are not CNC-Ready.

The stand-alone controller is programmable via its integrated keypad and controls the attached stepper motor, which can be mounted on the mill’s X- or Y-axis or the lathe’s crosslide. (For lathe leadscrew upgrades, click here for 15″ upgrade kits or click here for 24″ kits.)

An 8-pin mini-DIN cable allows multiple controllers to be connected in a “daisy-chain” configuration. Controllers can signal one another to run in sequence, enabling complex, multi-axis movements without a computer or master CNC controller. The controller also integrates easily with existing CNC systems. Each controller stores two independent programs with up to 40 steps per program. Each step can define travel distance, direction, feed rate, and whether the sequence pauses or continues automatically.

The linear controller can also be daisy-chained with Sherline’s rotary controller (P/N 8700), allowing combined rotary and linear motion for advanced operations—such as gear cutting—without the need for CNC programming skills beyond simple keypad inputs.

Included with the CNC Linear Controller:

Linear controller with integrated keypad

Power supply

#23 frame size stepper motor

Cables

Stepper motor mount

Dampened coupling

Preload nuts

Drill guide block

Complete installation and operation instructions

Power Supply Compatibility:

The included power supply is compatible with 110–240 VAC and automatically adjusts for global use (220–240V). Earlier versions of this product shipped with a 110 VAC-only power supply.

-

| Power Supply | Input: 115 VAC 50/60 Hz, Output: 24V, 1 Watt |

|---|---|

| Stepper Motor | 100 oz-in, 2 Amp, #23 Frame size, 400 steps per revolution |

| Speed | 1″/min. to 25 in/min (programmable) |

| Distance | from 0.0005″ to 9.9995″ in steps of 0.0005″ |

| Backlash Compensation | Programmable |

| 12050 | (4) 8-32 x 3/8″ SHC Screw |

|---|---|

| 40520 | 10-32 x 3/16″ cup point set screw |

| 67102 | Stepper motor mount |

| 671052 | CNC Coupling |

| 67106 | CNC Coupling Preload nut (RH) |

| 67107 | CNC Coupling Preload nut (LH) |

| 67111 | (2) 8-32 x 7/8″ SHC Screw |

| 67115 | 5-40 x 7/8″ SHC Screw |

| 67117 | CNC Template, side bushing (rectangular) |

| 67120 | (2) Stepper motor preload bearing |

| 8800 (8810 metric) | Linear controller (for CNC-Ready) |

Related products

CNC Linear Controller with 15″ Leadscrew

This linear controller package includes a stepper motor mount and a 15" leadscrew for use on Sherline lathes that are not CNC-Ready. The stand-alone controller is programmable through its integrated keypad and directly controls the attached stepper motor, which is mounted to drive the lathe’s leadscrew. (A separate kit with a 24" leadscrew is available for 4400-series lathes—P/N 8880.)

An 8-pin mini-DIN cable allows multiple controllers to be connected in a “daisy-chain” configuration. The controllers can signal each other to operate in sequence, enabling complex multi-axis operations without the need for a computer or master CNC controller. The system can also be used in conjunction with existing CNC controllers. Each unit can store two separate programs, with up to 40 steps per program. For each step, you can define travel distance, direction, feed rate, and whether the sequence pauses or advances automatically.

The linear controller can also be daisy-chained with Sherline’s rotary controller (P/N 8700), allowing coordinated rotary and linear motion. This makes it easy to perform sophisticated operations—such as gear cutting—without any CNC programming knowledge beyond the keypad interface.

Advantages of Using a Power Feed:

Maintains a constant feed rate for smoother, more consistent surface finishes

Minimizes errors from miscounting handwheel revolutions

Eliminates physical effort during long cuts or when returning the saddle to the starting position

Programming is simple and intuitive. Stored programs can be run repeatedly at the push of a button with excellent repeatability and accuracy.

Included with the CNC Linear Controller:

Linear controller with keypad

Power supply

#23 frame size stepper motor

Cables

Stepper motor mount

15" leadscrew

Dampened coupling

Preload nuts

Drill guide block

Complete installation and operating instructions

Power Supply Compatibility:

The included power supply operates on 110–240 VAC and automatically adjusts for global use (220–240V). Earlier models of this product shipped with a 110 VAC-only power supply.

CNC Linear Controller with 24″ Leadscrew

This CNC power feed includes a stepper motor mount and a 24" leadscrew for use with Sherline lathes that are not CNC-Ready. The stand-alone controller is programmable through its integrated keypad and directly controls the attached stepper motor, which can be mounted to drive the leadscrew of the lathe.

An 8-pin mini-DIN cable allows multiple controllers to be connected in a “daisy-chain” configuration. Controllers can signal one another to operate in sequence, enabling complex multi-axis movements without requiring a computer or master CNC controller. The controller can also be used in combination with existing CNC systems. Each unit is user-programmable with two independent programs of up to 40 steps each. For each step, you can set travel distance, direction, feed rate, and whether the sequence pauses or proceeds automatically.

The linear controller can also be daisy-chained with Sherline’s rotary controller (P/N 8700) to combine rotary and linear movements. This makes it easy to perform advanced tasks—such as gear cutting—without any CNC programming knowledge beyond the keypad interface.

Advantages of Using a Power Feed:

Provides a constant feed rate for a smoother, more consistent surface finish

Reduces the chance of errors caused by miscounting handwheel revolutions

Eliminates physical effort for long cuts or returning the saddle to the starting position

Programming is quick and straightforward. Stored programs can be executed repeatedly at the touch of a button with high precision.

Included with the CNC Linear Controller:

Linear controller with integrated keypad

Power supply

#23 frame size stepper motor

Cables

Stepper motor mount

24" leadscrew

Dampened coupling

Preload nuts

Drill guide block

Complete installation and operating instructions

Power Supply Compatibility:

The included power supply operates on 110–240 VAC and automatically adjusts for international use (220–240V). Earlier versions of this product were supplied with a 110 VAC-only power supply.

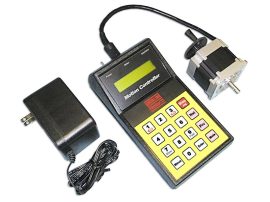

CNC Linear Controller with Stepper Motor

This stand-alone controller is fully programmable via its integrated keypad and directly controls the stepper motor to which it is connected. The stepper motor can be applied to any axis of a CNC-Ready Sherline machine.

An 8-pin mini-DIN cable allows multiple controllers to be connected in a “daisy-chain” configuration. Controllers can signal one another to operate in sequence, enabling complex, multi-axis movements without the need for a computer or master CNC controller. The system can also be used alongside existing CNC controllers. Each controller stores two independent programs, with up to 40 operations per program. For each operation, you can define travel distance, direction, feed rate, and whether the sequence pauses or proceeds to the next step.

The linear controller can also be daisy-chained with Sherline’s rotary controller, enabling coordinated rotary and linear motion. This allows users to easily perform advanced operations—such as gear cutting—without requiring CNC programming skills beyond simple keypad inputs.

Included with the CNC Linear Controller:

Linear controller with keypad

Power supply

#23 frame size stepper motor

Cables

Complete instructions

Note: To add CNC linear control to an axis on a Sherline machine that does not have a stepper motor mount, see P/N 8850.

Power Supply Compatibility:

The included power supply operates on 110–240 VAC and automatically adjusts for global use (220–240V). Earlier versions of this product shipped with a 110 VAC-only power supply.

Stepper Motor

Sherline stepper motors feature shafts at both ends, allowing for manual control via a handwheel, if desired. Flats are ground onto each shaft to accommodate set screws for the handwheel and coupling. For use with a Sherline motor mount, ensure that the shaft entering the coupling has a flat machined or ground onto it where the set screw secures it. Failure to do so may damage the shaft, making the coupling difficult to remove. For non-Sherline applications, the flat may not be necessary.

Powerful Dual-Shaft Motors

P/N 67127: This motor comes pre-wired with six leads in a connector that plugs directly into Sherline's linear or rotary controllers. Both our CNC system and driver box include four pre-wired cables with 5-pin plugs that match the P/N 67127 stepper motor. Simply plug each stepper motor into the corresponding axis cable for an easy setup.

P/N 67130: This motor features six raw wire leads, and does not include a connector, so that it can be used with non-Sherline controllers that have a different pin configuration.

Note: Due to the lack of standardization in the industry, wire colors can vary between suppliers. If using a connector not supplied by Sherline we recommend using a continuity checker to identify which wire connects to each pin on the DIN plug. Typically, the black and white (or tan) wires are connected to the center pins, but other colors may vary. See our specifications sheet for wiring diagram.