Quick-Change 3/8″ Square Shank Tool Holder

55° RH and LH Tool Holders w/Carbide Inserts

These tool holders are available individually in right-hand or left-hand configurations, or as a matched pair. Each holder includes a 55° carbide insert, a hold-down screw, and a Torx® key for installation. Designed with a 3/8" square shank, they fit standard 3/8" tool posts, and the insert tip is precisely 0.375" from the base of the holder—an industry-standard dimension.

The 5° offset angle of the cutting tip provides added versatility for certain operations. For example, when the holder is squared with the crosslide, it allows you to turn an outside diameter (O.D.) up to a shoulder and then finish the shoulder by backing the tool out—while maintaining proper tool clearance.

Constructed from case-hardened steel with a durable black oxide finish, these holders are built for long-lasting performance.

Although carbide insert tools are more costly than high-speed steel (HSS) tools, they offer an advantage: when the cutting edge becomes dull or chipped, you can simply rotate the insert 180° to use the second edge—essentially giving you two tools in one.

While HSS tools remain the primary choice for miniature machining due to their low cost, resharpenability, and adaptability for custom form tools, carbide insert tools are invaluable for specific applications. They maintain a sharp edge when cutting hard or abrasive materials, reduce tool wear, and allow for faster machining—reasons why they're widely used in professional machine shops.

Note: Tool orientation is named by the direction the chip exits the tool. A right-hand tool has its cutting edge on the left, and the chip peels off to the right.

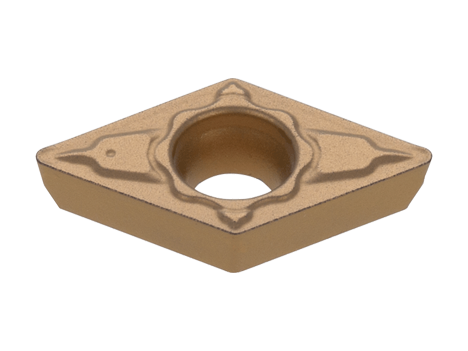

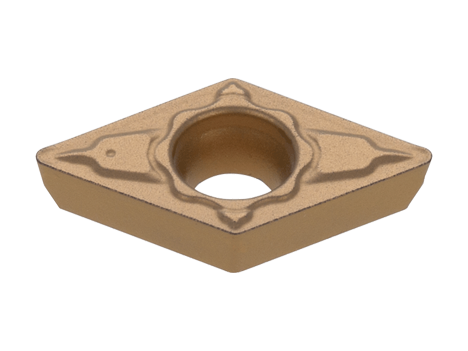

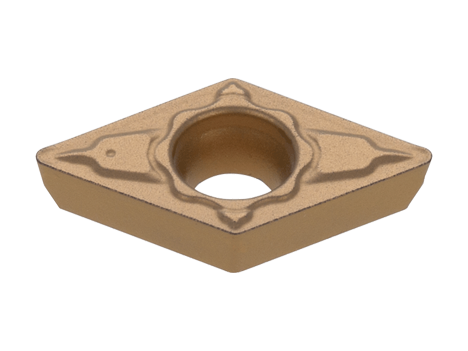

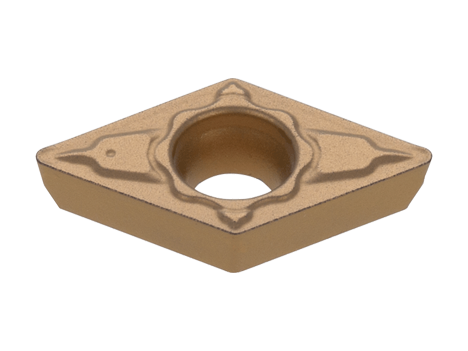

Updated Note: The previously used straight-groove chip breaker insert shown in some images is no longer available. All current inserts now come with the spider web-style chip breaker as shown here.

80° RH and LH Tool Holders w/Carbide Inserts

These holders are available individually in right-hand and left-hand configurations, or as a matched pair. Each includes an 80° carbide insert, a hold-down screw, and a Torx® key for installation.

Specifications & Features:

-

3/8" square shank, compatible with standard 3/8" insert tool posts

-

5° offset angle provides better tool clearance for complex operations

-

Tip height is 0.375" from the base, meeting industry standards

-

Constructed from case-hardened steel with a durable black oxide finish

-

80° inserts are ideal for roughing cuts

-

55° insert holders are also available for sharper corner access

For example, when the holder is squared with the crosslide, it allows you to turn an O.D. up to a shoulder, then finish the shoulder by backing the tool out—while maintaining proper clearance throughout the cut.

Advantages of Inserted Tip Carbide Tools

Although more expensive than high-speed steel (HSS), carbide inserts offer key benefits:

-

Each insert can be rotated 180°, giving you two cutting edges per insert

-

Maintain a sharp edge when cutting exotic alloys or abrasive materials

-

Enable faster cutting speeds and improved surface finishes

While HSS tools are ideal for general use due to their affordability and ease of resharpening, carbide tools are essential for challenging jobs, which is why they're widely used in professional machine shops.

Note: Tool orientation is based on the direction of chip flow. A right-hand tool has its cutting edge on the left, with chips exiting to the right.

Chip Breaker Update: The previously used straight-groove chip breaker is no longer available. Current inserts now come with the improved spider web-style chip breaker, as shown in the updated product images.

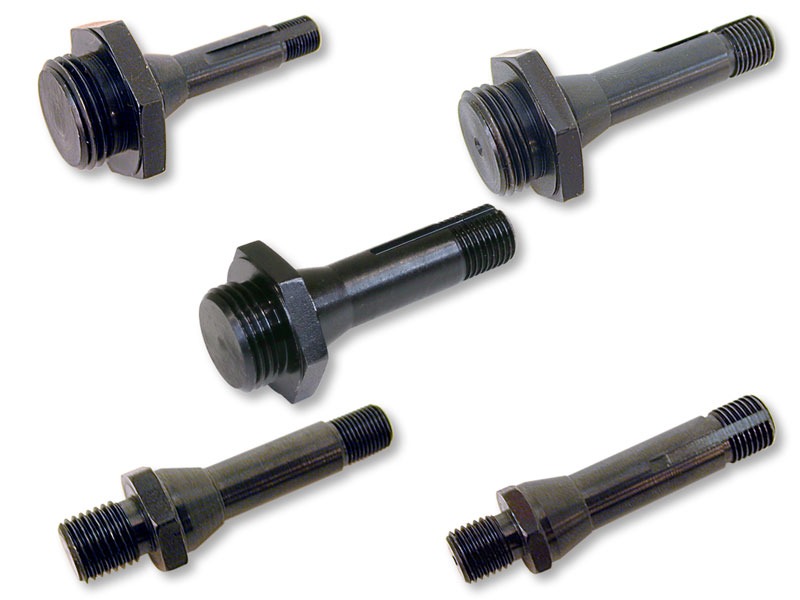

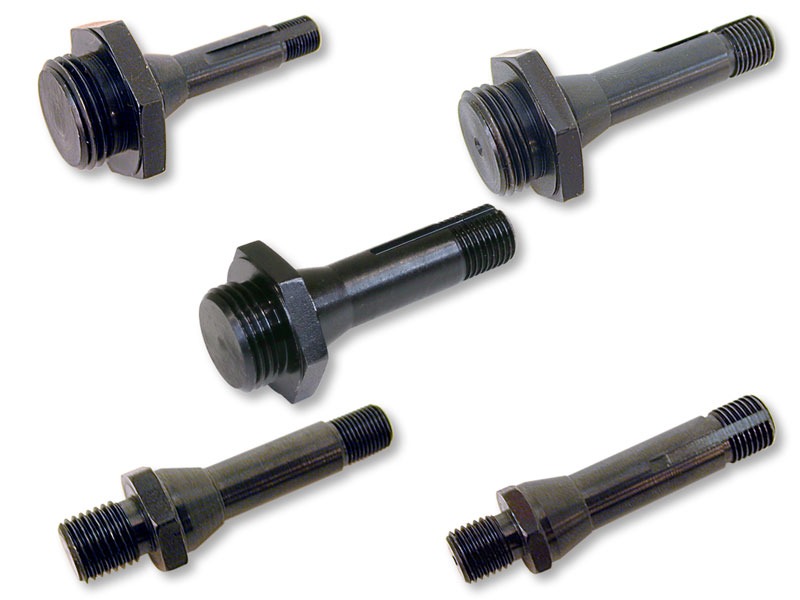

RH 55° and 80° 3/8″ Boring Bars w/Carbide Inserts

These 3/8" diameter boring bars feature a carbide insert secured with a Torx® screw and come complete with a Torx wrench. Choose between:

-

A 55° right-hand insert, suitable for starting holes as small as 3/4", ideal for reaching sharp internal corners

-

An 80° insert, which fits into a smaller 1/2" hole and offers added strength for roughing operations

Each holder measures 3-1/4" long and can bore to a depth of just over 2" when properly secured with two set screws. Manufactured from durable 1144 Stressproof® steel with a black oxide finish, these tools are available individually or as a discounted set.

Why Choose Carbide Insert Tools?

While high-speed steel (HSS) remains common for small machine tools due to its low cost and resharpenability, carbide inserts offer significant advantages in demanding applications:

-

Longer-lasting edges when cutting hard metals like stainless steel, titanium, or abrasive materials such as carbon fiber

-

Faster cutting speeds and greater efficiency

-

Each insert can be rotated 180°, effectively giving you two cutting edges per insert

Although carbide inserts can't be resharpened, their durability and versatility make them a preferred choice in professional machine shops.

Note: The older straight-groove chip breaker insert is no longer available. Current inserts include the spider web-style chip breaker, as shown in the updated images here & here

LH 55° & 80° 3/8″ Boring Bars w/Carbide Inserts

These 3/8" diameter boring bars hold a carbide insert secured with a Torx screw. Each comes with either a 2-sided 55° or 80° carbide insert and Torx wrench. The 55° LH boring tool will fit into a 3/4" starting hole. The 80° holder will fit into a smaller 1/2" hole. The 80° holder offers a little more strength for roughing cuts while the 55° insert will cut into sharper corners. The 3-1/4" long holder can bore a hole a little over 2" deep with two fastening screws tightened on it. The holders are made from 1144 Stress-proof steel with a black oxide finish. Available individually.

Left Hand Boring Bars

These LH boring bars are not intended to be used for boring on a standard Sherline lathe, as the spindle is not reversible without electronic modifications. They were developed for a Sherline tool that is now in development where they will be used as a turning tool from the backside with the bit upside down. Watch for the introduction of this new “chucker” lathe soon.

Advantages of Using Carbide Insert Tools

Though relatively expensive, if a cutting edge of a carbide insert becomes dull or chipped, the insert can be removed and rotated 180° to expose two new cutting surfaces, providing, in effect, two tools for the price of one.

The primary method of cutting metal on miniature machine tools is usually with high-speed steel tools as they are inexpensive, easily resharpened and can be ground into "form" tools for special jobs. However, inserted tip carbide tools can be lifesavers for some jobs. Though more expensive and not able to be resharpened, carbide tools hold their cutting edge when cutting exotic metals like stainless steel or titanium or abrasive materials like carbon fiber and can speed up the cutting process. This is why they are used for most cutting tasks in the modern professional machine shop.

NOTE: A tool is named by the direction from which the chip leaves the tool; so a right-hand tool has its cutting edge on the left and the chip peels off to the right.

1/4″ HSS Tool Blank Set

Lathe tools—also known as tool bits—are the cutting tools used for turning, facing, and other operations on a lathe. The most commonly used are high-speed steel (HSS) tools, which are suitable for machining a wide range of materials including wood, plastic, aluminum, brass, and steel. HSS tools maintain their hardness at temperatures up to 1000°F (588°C), making proper depth of cut, cutting speed, and feed rate essential for optimal performance.

One of the key advantages of HSS tools is how easily they can be resharpened using a standard aluminum oxide grinding wheel. Once sharpened, they retain a keen cutting edge through extended use.

Each Sherline lathe comes with a pre-sharpened 1/4" HSS cutting tool. Pre-ground tool sets—featuring right-hand, left-hand, and boring tools—are also available. However, for long-term savings and flexibility, learning to grind your own tools from blanks is recommended. Custom-shaped tools can be saved for repeat jobs or re-ground for new applications.

Slitting Saws

Each saw blade is 2" in diameter with a 1/2" hole. The saw blades come in varying thicknesses and teeth counts. They require the slitting saw holder, which is held in the spindle with a drawbolt that pulls the holder up into the Morse #1 taper.

Note: Due to supply chain issues, the outside diameter of some of our saw blades may be 2-1/2" instead of 2" and teeth counts can vary. If you need a specific number of teeth in a certain size, please contact us to see if we have them in stock

55° Carbide Insert

While not inexpensive, carbide inserts offer excellent value—each insert provides four cutting edges, significantly reducing the need for frequent sharpening and saving valuable time.

Carbide cutters perform well on hard-to-machine materials like cold-rolled steel and are also effective on aluminum, brass, and leaded steels, offering exceptional durability. However, for the finest finishes on softer metals, a well-sharpened high-speed steel tool still delivers superior results.

This is the 10-pack of replacement carbide inserts for the following tool holders:

55° Carbide Insert-10 Pack

While not inexpensive, carbide inserts offer excellent value—each insert provides four cutting edges, significantly reducing the need for frequent sharpening and saving valuable time.

Carbide cutters perform well on hard-to-machine materials like cold-rolled steel and are also effective on aluminum, brass, and leaded steels, offering exceptional durability. However, for the finest finishes on softer metals, a well-sharpened high-speed steel tool still delivers superior results.

This is the 10-pack of replacement carbide inserts for the following tool holders:

80° Carbide Insert

While carbide inserts may have a higher upfront cost, they offer excellent value by providing four usable cutting edges per insert and significantly reducing time spent on tool sharpening.

Carbide cutters excel at machining difficult materials such as cold-rolled steel, stainless steel, and bronze, delivering consistent performance and long tool life. They are also compatible with aluminum, brass, and leaded steels—though for these softer materials, a finely honed high-speed steel tool may still yield the best surface finish.

This is the 10-pack of replacement carbide inserts for the following tool holders:

80° Carbide Insert-10 Pack

While carbide inserts may have a higher upfront cost, they offer excellent value by providing four usable cutting edges per insert and significantly reducing time spent on tool sharpening.

Carbide cutters excel at machining difficult materials such as cold-rolled steel, stainless steel, and bronze, delivering consistent performance and long tool life. They are also compatible with aluminum, brass, and leaded steels—though for these softer materials, a finely honed high-speed steel tool may still yield the best surface finish.

This is the 10-pack of replacement carbide inserts for the following tool holders:

Carbide Inserts (thread, groove)

These Carbide inserts are used in the Insert Tool Holder and are used for either threading or grooving.

Thread Cutting

- 60° threading insert for cutting outside threads (P/N 22675)

- .031" insert (P/N 2269)

- .062" insert (P/N 2270)

- .094" insert (P/N 22694)

- .125" insert (P/N 22695)

- .031" radius insert (P/N 22692)

- .062" radius insert (P/N 22693)

3-piece Center Drill Set

Center drills are essential for accurately drilling starter holes in the ends of workpieces, particularly when mounting stock between centers on a lathe. Each drill creates a small pilot hole followed by a 60° countersink, which provides a seating surface for the 60° point of the lathe center.

In milling applications, center drills are commonly used to start holes precisely. The exact hole location can be dialed in using the mill’s calibrated handwheels, and the center drill ensures the hole begins accurately without drifting.

This set includes three double-ended, high-speed steel (HSS) center drills:

-

#1 drill: 1/8" shank

-

#2 drill: 3/16" shank

-

#3 drill: 1/4" shank

The larger shank diameter of a center drill ensures the tip remains centered, reducing the risk of the drill "walking" as the hole is started. After the center drill has established the starter hole, it is replaced with a standard drill bit to complete the hole to the desired diameter.

⚠️ CAUTION: Always use a suitable cutting lubricant and back the drill out frequently during use. This prevents the delicate tip from overheating or breaking off.

Spur Driver

The spur driver is used in the headstock to drive wood when turning between centers, rather than using the 3-jaw chuck. The body has a #1 Morse taper. It has a center point and four “teeth” that bite into the … Continued

Thread-Cutting Attachment

A key advantage of owning a lathe is the ability to machine threads. While taps and dies can cut many threads, acquiring a comprehensive tap and die set to cover all non-standard thread sizes can be costly. Sherline provides a unique and versatile thread-cutting attachment for its lathe. This affordable attachment enables you to machine thirty-six different unified thread pitches (ranging from 80 to 5 threads per inch) and twenty-eight different metric thread pitches (ranging from .25 to 2.0 mm). It also allows for both left-hand and right-hand threading. A 60° carbide cutting tool is included, but you can also grind a standard high-speed steel tool to cut various thread forms at any pitch diameter. This versatility allows you to machine both standard and non-standard inside or outside threads, as long as they fall within the lathe’s size limitations.

Note: Ensure you lubricate the gears with light oil before using the threading attachment.

The attachment includes:

- 15 aluminum gears

- Mounting brackets

- Engagement mechanism

- 4.00" (102 mm) handwheel

Thread cutting on the Sherline lathe is accomplished by gearing the spindle to the leadscrew. As the spindle is rotated using the handwheel mounted on the headstock spindle, the tool advances according to the gear ratio. Once the tool reaches the end of its movement, simply stop cranking, reverse the tool, and turn the spindle in the opposite direction until the tool passes its starting point. Reset the tool, and you’re ready for the next pass. It’s as straightforward as tapping! By using the supplied 127-tooth gear, you can cut true metric threads on an inch lathe or true inch threads on a metric lathe.

⚠️ Note: The thread-cutting attachment is not compatible with the 3C Headstock.

Adapting the Leadscrew Engagement Lever for Use with Digital Readout (DRO)

If you plan to use the leadscrew engagement lever with the Thread Cutting Attachment in conjunction with a Digital Readout (DRO), you will need to equip your lathe with the DRO sliding shaft (sold separately) for proper leadscrew engagement.Gear Selection Calculator

The Sherline Thread Attachment Calculator, created by Joo Beng Koh of Singapore, automates gear selection based on your desired thread count. Originally shared on the Sherline Lathe & Mill Facebook Group, Joo Beng graciously allowed us to feature this tool on our website. The calculator simplifies the setup process, particularly for users who frequently change their thread specifications.

For instructions, select the desired parameters in the light yellow fields, and the corresponding gear selections will appear in the green boxes. An accompanying image shows the correct gear placement along with step-by-step guidance for installation. This tool has greatly improved the process for Joo Beng and can help others as well.

Click here for Joo Beng Koh's Sherline Thread Attachment Calculator.

More Calculators

Visit our Calculators page to explore additional tools for gear tooth and thread calculations, including calculators for thread counts, helical gears, conversions, and more.

Lathe Headstock Hard Stop Kit