Ceramic Insert Tool Holder

Designed for cutting hard materials like tool steel, this ceramic insert tool holder features a triangular insert mounted at a negative rake angle. The downward tilt of the insert provides proper side clearance, allowing you to use all six cutting edges—three per side—before needing a replacement. The 3/8" shank fits Sherline’s P/N 7600 tool post (not included). A clamp, hold-down screw, and 3/32" hex key are included for secure installation. Replacement inserts are available as (P/N 22659).

Why Use Ceramic Inserts?

Ceramic cutting tools are a powerful addition to the modern machinist’s toolbox. Though more brittle than high-speed steel (HSS) or carbide, ceramic inserts excel at cutting hardened steels and other tough materials, especially at higher spindle speeds. This makes them ideal for jobs that would otherwise be extremely difficult or impossible—such as turning down the shank of an end mill.

This insert’s large nose radius helps achieve an excellent surface finish, particularly when profiling.

-

Each insert offers six usable cutting edges:

-

Rotate 120° to access a new edge (3 per side), then

-

Flip the insert for 3 more cutting points on the opposite face

-

-

In comparison, traditional carbide inserts offer only 2–4 cutting edges, making ceramic inserts cost-effective over time, despite the higher upfront cost.

Usage Notes & Safety Information

-

Ceramic inserts are brittle and should be used with proper technique to avoid chipping or breakage.

-

Caution: Chips produced during cutting can be extremely hot—even red-hot. Use protective eyewear, gloves, and fire-safe clothing when operating.

-

Some materials, such as tool steel, may form long, stringy chips that wrap around the part ("bird’s nest" effect).

Use a chip brush and stop the machine frequently to clear chips. These chip clusters can ignite if they come in contact with hot chips.

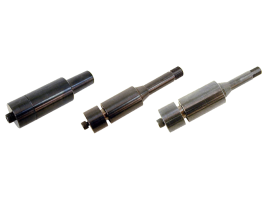

Threading/Grooving Carbide Insert Tool Holder

Due to the variety of insert types and their cost, the holder is sold separately without inserts, allowing you to select only the specific inserts you need. The holder includes a clamp, 6-32 hold-down screw, and a 7/64" hex key for secure setup.

⚠️ CUSTOMER NOTICE — July 8, 2020

We’ve identified a potential issue affecting a small number of our Threading/Grooving Carbide Insert Tool Holders. Specifically, the cutting insert may not be securely clamped in place.

When tightening the clamp, the inside corner of the clamp may contact the step adjacent to the insert pocket, preventing full engagement with the clamping notch on the insert. This was caused by an early in-house clamp design that mistakenly used symmetrical angles on both sides of the clamp nose, rather than the intended asymmetrical design. This issue has since been corrected.

[caption id="attachment_33596" align="alignright" width="300"] Click on the image for a larger view.[/caption]

Click on the image for a larger view.[/caption]

To resolve the issue immediately:

-

Use a bench grinder or file to slightly grind down the back side of the clamp (see blue circle in the image).

-

This will allow the clamp tip to clear the step (indicated by the red arrow), ensuring full contact and proper clamping of the insert.

⚠️ CAUTION: Chips coming off the carbide inserts can be very HOT! Use extreme caution. Carbide inserts can also shatter. For these reasons, proper protective eyewear and clothing are especially important when using these tools. Materials like tool steel can form long, stringy chips that wrap around the part. Use a chip brush frequently, or pause machining to clear debris. Accumulated chips, especially when hot, can ignite. Keep the area around the cutter clean and free of chip buildup.

3/8″ Rear-Side Cutoff Multi-Tool Holder

5/8″ Rear-Side Cutoff Multi-Tool Holder

Pool Cue Live Center

Adjustable Tailstock 1″ Die Holder

Adjustable Tailstock Custom Tool Holder

#0 Morse to 3/4-16 Chuck Adapter

This adapter fits into the #0 Morse taper of the tailstock to allow Sherline chucks with a 3/4-16 spindle thread to be mounted to the tailstock for holding tools or work. This is a simple and inexpensive way to increase … Continued

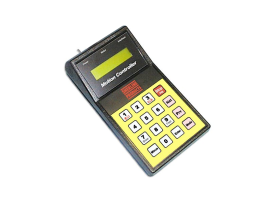

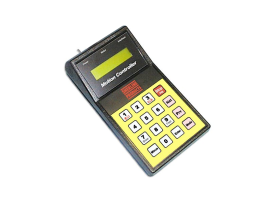

Linear Controller without Power Supply

The stand-alone controller is fully programmable via its built-in keypad and manages the operation of the connected stepper motor.

An 8-pin mini-DIN cable allows multiple controllers to be linked in a "daisy-chain" configuration. The controllers can signal each other to operate in sequence, enabling complex, multi-axis movements without the need for a computer or master CNC controller. They can also be used alongside existing CNC systems. Each controller can store two independent programs, with up to 40 steps per program. Each step can define distance, direction, speed, and whether the program pauses or proceeds automatically to the next step.

Sherline’s linear controller can also be daisy-chained with the rotary controller, allowing combined rotary and linear operations in sequence. This setup simplifies advanced tasks—such as gear cutting—without requiring CNC programming knowledge beyond what is entered via the keypad.

Items Included with the Linear Controller:

-

Linear controller with integrated keypad

Controller Power Supply Information:

The optional power supply is compatible with 110-240 VAC and automatically switches between voltages for use in regions with 220-240V mains power. (The original version of this power supply was 110 VAC only.)

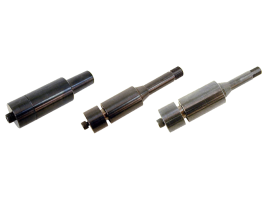

Individual WW Collets

Collets offer a fast and accurate way to mount cylindrical parts or bar stock in a lathe. Each collet functions like a miniature precision 3-jaw chuck and fits into a tapered adapter mounted in the headstock. A drawbar passes through the headstock and threads into the rear of the collet, pulling it into the adapter. This action causes the collet jaws to close and securely grip the workpiece. Collets are known for their exceptional centering accuracy, but each collet size accommodates only a limited diameter range—typically ±.001" (0.02 mm).

WW Collets vs. Milling Collets

Unlike milling collets, WW collets feature a through-hole, allowing material to pass completely through both the collet and drawbar. The maximum diameter stock that can pass through is 3/16" (4.5 mm), although WW collets are available in sizes up to 5/16" (8.0 mm). Collets larger than the through-hole capacity are sometimes referred to as “pot chucks,” as they are only bored to a depth of approximately .260".

Collet Accuracy

Sherline WW collets are precision-made and have a maximum runout of .002" or less. When the WW collet adapter is properly trued as recommended in the instructions, runout is minimized, providing optimal accuracy. Pot chucks (collets larger than 3/16" or 4.5 mm) are not bored through and may exhibit increased runout if your part extends far beyond the front of the collet.

Logical Part Numbering

Sherline collets are organized by size for easy identification:

-

Inch Collets: Part numbers begin with 1160, followed by two digits representing the size in 64ths of an inch.

-

Example: P/N 116013 is 13/64"; P/N 116016 is 1/4" (16/64").

-

-

Metric Collets: Part numbers begin with 1178, followed by two digits representing the size in 0.1 mm increments.

-

Example: P/N 117813 is 1.3 mm.

-

Compatibility and Specifications

Sherline WW collets are manufactured in-house to standard WW specifications but are not hardened. The shank diameter is .312–.313", and the thread is .275-40. While some third-party WW collets may not fit properly, Sherline offers an optional .315" adapter and drawbar set (P/N 1163) to accommodate select 8 mm collets from other manufacturers.

Available Sizes

Sherline WW collets are offered in:

-

Inch sizes from 1/64" to 5/16", in 64th-inch increments.

-

Metric sizes from 0.3 mm to 8.0 mm, in 0.1 mm increments.

Special inch sizes up to .320" can be custom ordered with approximately a 3-week lead time. Please contact us for details.

Quck Order

If you are ordering a lot of different size collets please use the quick order table below to make it easier!

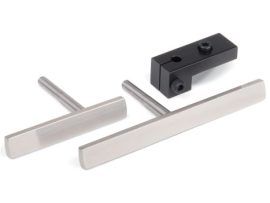

Headstock Riser Block Set

The standard Sherline lathe can accommodate parts up to 3.5" (90 mm) in diameter. However, there are times when you may need to work on larger pieces. The Sherline headstock spacer block increases the lathe’s maximum working diameter to 6" (152 mm), significantly expanding its capabilities.

This set includes a 1.235" (31.37 mm) spacer block that fits beneath the headstock, along with a riser-rocker tool post to elevate the cutting tool accordingly. If you plan to turn parts between centers while using the headstock riser, you’ll also need a tailstock riser block to maintain proper alignment.

Note: Although the spacer block allows turning parts up to 6" in diameter, the lathe’s motor power remains unchanged. This accessory is best suited for machining easy-to-cut materials or for occasional use when extra clearance is needed. If your work frequently requires this added capacity, upgrading to a larger lathe may be advisable.