2-Axis Lathe DRO

Lathe DRO with CNC Thrust Collars

2-Axis Lathe DRO with CNC Thrust Collars without Readout Box

2-Axis Lathe DRO without Readout Box

3-Axis Lathe DRO

3-Axis Lathe DRO with CNC Thrust Collars

Z-Axis DRO Handwheel Package

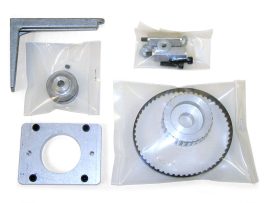

Horological Milling Machine Bushing and Depthing Accessory

This accessory was developed based on a concept shared by longtime Sherline user and Craftsman of the Year, Jerry Kieffer. The idea is to adapt a small milling machine for multiple clock and watch repair tasks - replacing the need for several specialized tools. It simplifies and enhances depthing by letting you position a gear exactly where it needs to be, check its mesh with a mating gear, and then precisely machine the bushing hole in the correct location.

With the Sherline mill, you can precisely position and align clock and watch components, allowing for highly accurate machining of bushing holes in both size and location. Once the machining is complete, the mill can also serve as a manual press for bushing insertion.

Used in combination with your Sherline mill, this accessory transforms your setup into a versatile three-in-one clock and watch repair machine - while retaining the full functionality of a precision milling machine.

The photos show the depthing attachment on a 5400 mill. If you want to use it on a 5000-series mill you will need to add the headstock spacer block.

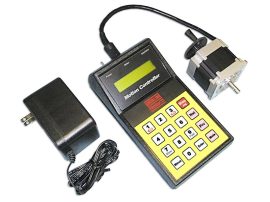

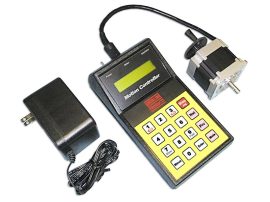

CNC Linear Controller with Power Supply

This stand-alone controller features an integrated keypad for easy programming and controls the operation of the connected stepper motor—no external computer or CNC system is required.

An 8-pin mini-DIN cable allows multiple controllers to be connected in a daisy-chain configuration. Each unit can send and receive signals to operate in sequence, enabling multi-axis motion without a master CNC controller. The controllers can also interface with existing CNC systems for more complex setups.

Each controller supports two independent programs, with up to 40 steps per program. Each step can define travel distance, direction, speed, and whether to pause or automatically continue to the next command.

The linear controller can also be daisy-chained with Sherline’s rotary controller, enabling combined linear and rotary motion. This simplifies more advanced tasks—such as gear cutting—without requiring any G-code knowledge beyond the simple keypad inputs.

Included with the Linear Controller:

-

Linear Controller with Keypad

-

Power Supply

Power Supply Specifications:

The included power supply is compatible with 110–240 VAC and automatically adjusts to local voltage, making it suitable for use worldwide. (Earlier versions of this product included a 110 VAC-only power supply.)

X-Axis DRO Handwheel package

Y-Axis DRO Handwheel package

CNC Linear Controller with 15″ Leadscrew

This linear controller package includes a stepper motor mount and a 15" leadscrew for use on Sherline lathes that are not CNC-Ready. The stand-alone controller is programmable through its integrated keypad and directly controls the attached stepper motor, which is mounted to drive the lathe’s leadscrew. (A separate kit with a 24" leadscrew is available for 4400-series lathes—P/N 8880.)

An 8-pin mini-DIN cable allows multiple controllers to be connected in a “daisy-chain” configuration. The controllers can signal each other to operate in sequence, enabling complex multi-axis operations without the need for a computer or master CNC controller. The system can also be used in conjunction with existing CNC controllers. Each unit can store two separate programs, with up to 40 steps per program. For each step, you can define travel distance, direction, feed rate, and whether the sequence pauses or advances automatically.

The linear controller can also be daisy-chained with Sherline’s rotary controller (P/N 8700), allowing coordinated rotary and linear motion. This makes it easy to perform sophisticated operations—such as gear cutting—without any CNC programming knowledge beyond the keypad interface.

Advantages of Using a Power Feed:

-

Maintains a constant feed rate for smoother, more consistent surface finishes

-

Minimizes errors from miscounting handwheel revolutions

-

Eliminates physical effort during long cuts or when returning the saddle to the starting position

Programming is simple and intuitive. Stored programs can be run repeatedly at the push of a button with excellent repeatability and accuracy.

Included with the CNC Linear Controller:

-

Linear controller with keypad

-

Power supply

-

#23 frame size stepper motor

-

Cables

-

Stepper motor mount

-

15" leadscrew

-

Dampened coupling

-

Preload nuts

-

Drill guide block

-

Complete installation and operating instructions

Power Supply Compatibility:

The included power supply operates on 110–240 VAC and automatically adjusts for global use (220–240V). Earlier models of this product shipped with a 110 VAC-only power supply.

CNC Linear Controller with 24″ Leadscrew

This CNC power feed includes a stepper motor mount and a 24" leadscrew for use with Sherline lathes that are not CNC-Ready. The stand-alone controller is programmable through its integrated keypad and directly controls the attached stepper motor, which can be mounted to drive the leadscrew of the lathe.

An 8-pin mini-DIN cable allows multiple controllers to be connected in a “daisy-chain” configuration. Controllers can signal one another to operate in sequence, enabling complex multi-axis movements without requiring a computer or master CNC controller. The controller can also be used in combination with existing CNC systems. Each unit is user-programmable with two independent programs of up to 40 steps each. For each step, you can set travel distance, direction, feed rate, and whether the sequence pauses or proceeds automatically.

The linear controller can also be daisy-chained with Sherline’s rotary controller (P/N 8700) to combine rotary and linear movements. This makes it easy to perform advanced tasks—such as gear cutting—without any CNC programming knowledge beyond the keypad interface.

Advantages of Using a Power Feed:

-

Provides a constant feed rate for a smoother, more consistent surface finish

-

Reduces the chance of errors caused by miscounting handwheel revolutions

-

Eliminates physical effort for long cuts or returning the saddle to the starting position

Programming is quick and straightforward. Stored programs can be executed repeatedly at the touch of a button with high precision.

Included with the CNC Linear Controller:

-

Linear controller with integrated keypad

-

Power supply

-

#23 frame size stepper motor

-

Cables

-

Stepper motor mount

-

24" leadscrew

-

Dampened coupling

-

Preload nuts

-

Drill guide block

-

Complete installation and operating instructions

Power Supply Compatibility:

The included power supply operates on 110–240 VAC and automatically adjusts for international use (220–240V). Earlier versions of this product were supplied with a 110 VAC-only power supply.

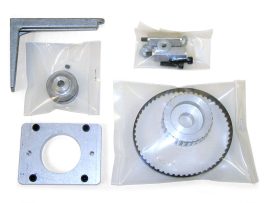

CNC Linear Controller – X/Y-Axis Upgrade

This kit upgrades the X- or Y-axis of a manual Sherline milling machine or the crosslide of a Sherline lathe for use with a CNC linear controller. It includes a CNC linear controller and all the components required to convert a manual axis to CNC operation. The linear controller comes with a stepper motor mount for machines that are not CNC-Ready.

The stand-alone controller is programmable via its integrated keypad and controls the attached stepper motor, which can be mounted on the mill’s X- or Y-axis or the lathe’s crosslide. (For lathe leadscrew upgrades, click here for 15" upgrade kits or click here for 24" kits.)

An 8-pin mini-DIN cable allows multiple controllers to be connected in a "daisy-chain" configuration. Controllers can signal one another to run in sequence, enabling complex, multi-axis movements without a computer or master CNC controller. The controller also integrates easily with existing CNC systems. Each controller stores two independent programs with up to 40 steps per program. Each step can define travel distance, direction, feed rate, and whether the sequence pauses or continues automatically.

The linear controller can also be daisy-chained with Sherline’s rotary controller (P/N 8700), allowing combined rotary and linear motion for advanced operations—such as gear cutting—without the need for CNC programming skills beyond simple keypad inputs.

Included with the CNC Linear Controller:

-

Linear controller with integrated keypad

-

Power supply

-

#23 frame size stepper motor

-

Cables

-

Stepper motor mount

-

Dampened coupling

-

Preload nuts

-

Drill guide block

-

Complete installation and operation instructions

Power Supply Compatibility:

The included power supply is compatible with 110–240 VAC and automatically adjusts for global use (220–240V). Earlier versions of this product shipped with a 110 VAC-only power supply.

CNC Linear Controller with Stepper Motor

This stand-alone controller is fully programmable via its integrated keypad and directly controls the stepper motor to which it is connected. The stepper motor can be applied to any axis of a CNC-Ready Sherline machine.

An 8-pin mini-DIN cable allows multiple controllers to be connected in a “daisy-chain” configuration. Controllers can signal one another to operate in sequence, enabling complex, multi-axis movements without the need for a computer or master CNC controller. The system can also be used alongside existing CNC controllers. Each controller stores two independent programs, with up to 40 operations per program. For each operation, you can define travel distance, direction, feed rate, and whether the sequence pauses or proceeds to the next step.

The linear controller can also be daisy-chained with Sherline’s rotary controller, enabling coordinated rotary and linear motion. This allows users to easily perform advanced operations—such as gear cutting—without requiring CNC programming skills beyond simple keypad inputs.

Included with the CNC Linear Controller:

-

Linear controller with keypad

-

Power supply

-

#23 frame size stepper motor

-

Cables

-

Complete instructions

Note: To add CNC linear control to an axis on a Sherline machine that does not have a stepper motor mount, see P/N 8850.

Power Supply Compatibility:

The included power supply operates on 110–240 VAC and automatically adjusts for global use (220–240V). Earlier versions of this product shipped with a 110 VAC-only power supply.