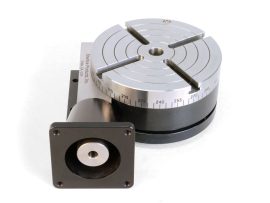

Nickel-Teflon Coated Manual Rotary Table

Nickel-Teflon Coated CNC-Ready Rotary Table

Nickel-Teflon Coated CNC Rotary Table with Stepper Motor

CNC Rotary Table with 36V Stepper Motor

CNC Rotary Table Indexer

Sherline has advanced its precision 4" rotary table into the 21st century with the addition of Computer Numerical Control (CNC). This upgrade makes it an ideal solution for clockmakers, gear cutters, and anyone needing to machine intricate radially symmetrical patterns. The CNC rotary table takes the complexity out of repetitive indexing tasks.

Complete, Stand-Alone System

Programming is done entirely through the integrated numeric keypad—no computer required. The system includes everything needed for operation:

-

4" Sherline rotary table with pre-installed stepper motor

-

Microprocessor unit with numeric keypad

-

115 VAC power supply (universal 110–240 VAC compatible)

-

All required connecting cables

Mounting Options

The rotary table includes clamps and T-nuts for mounting to the T-slots of a Sherline mill table. Additional options allow for flexible positioning:

-

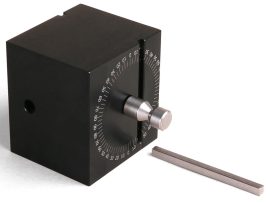

Right-Angle Attachment: Holds the table vertically at a 2.7" center height. A matching right-angle tailstock is also available for supporting long workpieces.

-

Tilting Angle Table: Allows mounting at any angle from 0° to 90°. At 90°, the center height remains 2.7", compatible with the right-angle tailstock.

Simple, Accurate Operation

Simply enter the steps per revolution (or degrees per step) via the keypad. The table advances precisely to the next position at the press of a button. If needed, previous positions can be recalled instantly.

-

Resolution: 28,800 steps per revolution

-

Accuracy: ±0.006° per step

This precision allows for accurate machining of gears with odd numbers of teeth, and built-in calculations prevent cumulative errors.

Flexible Integration

This CNC rotary indexer is a complete, stand-alone unit—perfect for complex indexing operations. It can also integrate with other CNC systems:

-

Accepts input signals from an external CNC controller

-

Sends “completion” signals back to the master controller

-

Can be daisy-chained with other units for coordinated actions

For more advanced applications, the rotary table can be linked with Sherline’s linear controller (P/N 8800), enabling seamless combinations of rotary and linear motion—ideal for gear cutting and other multi-axis operations, all without requiring advanced CNC programming knowledge.

Weight Capacity (Continuous Use)

-

Horizontal orientation: 50 lbs

-

Vertical orientation: 30 lbs

-

Vertical rotational torque: 6 ft-lbs (e.g., able to lift a 6 lb. weight 12" from the center)

Note: The table can handle heavier loads if not under continuous use. Refer to the Video tab for practical examples.

Power Supply

The controller power supply operates on 110–240 VAC and automatically adjusts for global use. (Earlier models included a 110 VAC-only power supply.)

Compatibility with Tilting Angle Table (TAT) Limit Switches

For instructions on using the rotary table with limit switches on the TAT, see the “Instructions” tab and download the PDF titled MASSO Rotary Table Limit Switch Interference on the Tilting Angle Table.

Nickel-Teflon Coated CNC-Rotary Table Indexer

CNC Rotary Controller with Stepper Motor

67127 2 Amp, 100-oz., 23 frame size stepper motor 87041 120 VAC power supply (24 VDC, 1 amp output) 87100 Control unit with keypad/electronics 87250 Motor-to-keypad 6’ extension cable 87350 Remote (limit) switch/daisy-chain 1/2 cable About the Controller Power Supply … Continued

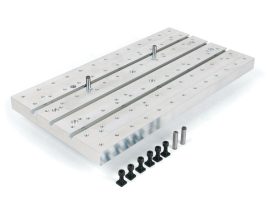

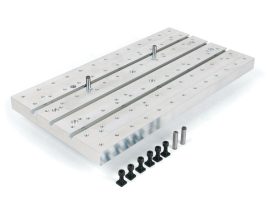

7″ x 13″ Mill Tooling Plate

7″ x 18″ Mill Tooling Plate

Chuck Adapters for Rotary Table

About the Rotary Table Chuck Adapters You can attach a 1/4″ or 3/8″ drill chuck, an older Unimat chuck with 12 x 1 mm or 14 x 1 mm threads, or a 1/2-20 Sears chuck to your Sherline rotary table. … Continued

Linear Controller without Power Supply

The stand-alone controller is fully programmable via its built-in keypad and manages the operation of the connected stepper motor.

An 8-pin mini-DIN cable allows multiple controllers to be linked in a "daisy-chain" configuration. The controllers can signal each other to operate in sequence, enabling complex, multi-axis movements without the need for a computer or master CNC controller. They can also be used alongside existing CNC systems. Each controller can store two independent programs, with up to 40 steps per program. Each step can define distance, direction, speed, and whether the program pauses or proceeds automatically to the next step.

Sherline’s linear controller can also be daisy-chained with the rotary controller, allowing combined rotary and linear operations in sequence. This setup simplifies advanced tasks—such as gear cutting—without requiring CNC programming knowledge beyond what is entered via the keypad.

Items Included with the Linear Controller:

-

Linear controller with integrated keypad

Controller Power Supply Information:

The optional power supply is compatible with 110-240 VAC and automatically switches between voltages for use in regions with 220-240V mains power. (The original version of this power supply was 110 VAC only.)

Drill Chuck Tool Holder

Mill Digital Readout (DRO)