Drill Chuck Tool Holder

2-Axis Lathe DRO

Lathe DRO with CNC Thrust Collars

2-Axis Lathe DRO with CNC Thrust Collars without Readout Box

2-Axis Lathe DRO without Readout Box

3-Axis Lathe DRO

3-Axis Lathe DRO with CNC Thrust Collars

Mill Digital Readout (DRO)

Mill DRO with CNC Thrust Collars

Mill DRO without Readout Box

Z-Axis DRO Handwheel Package

1″ End Mill Holder – Blank

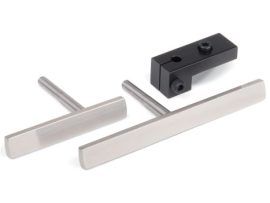

Machinist’s Parallel Bar Set

Parallel bars are precision-ground spacers used to elevate a workpiece by a known height while maintaining perfect parallelism with the machine table. This set includes five matched pairs made from 1018 steel, each measuring 2-1/2" long and 1/16" thick, with the following heights: 1/4" • 3/8" • 1/2" • 5/8" • 3/4"

Unlike the imported parallels previously offered, these are manufactured in-house by Sherline. Each bar is waterjet cut from 1/16" 1018 steel, ground to precise height tolerances, and finished with a durable black oxide coating to resist corrosion. This set reflects Sherline’s commitment to accuracy, quality, and American-made craftsmanship.

Chip Guard

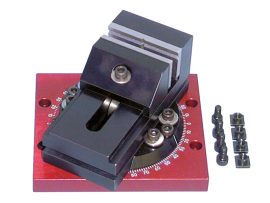

Horological Milling Machine Bushing and Depthing Accessory

This accessory was developed based on a concept shared by longtime Sherline user and Craftsman of the Year, Jerry Kieffer. The idea is to adapt a small milling machine for multiple clock and watch repair tasks - replacing the need for several specialized tools. It simplifies and enhances depthing by letting you position a gear exactly where it needs to be, check its mesh with a mating gear, and then precisely machine the bushing hole in the correct location.

With the Sherline mill, you can precisely position and align clock and watch components, allowing for highly accurate machining of bushing holes in both size and location. Once the machining is complete, the mill can also serve as a manual press for bushing insertion.

Used in combination with your Sherline mill, this accessory transforms your setup into a versatile three-in-one clock and watch repair machine - while retaining the full functionality of a precision milling machine.

The photos show the depthing attachment on a 5400 mill. If you want to use it on a 5000-series mill you will need to add the headstock spacer block.

CNC Linear Controller with Power Supply

This stand-alone controller features an integrated keypad for easy programming and controls the operation of the connected stepper motor—no external computer or CNC system is required.

An 8-pin mini-DIN cable allows multiple controllers to be connected in a daisy-chain configuration. Each unit can send and receive signals to operate in sequence, enabling multi-axis motion without a master CNC controller. The controllers can also interface with existing CNC systems for more complex setups.

Each controller supports two independent programs, with up to 40 steps per program. Each step can define travel distance, direction, speed, and whether to pause or automatically continue to the next command.

The linear controller can also be daisy-chained with Sherline’s rotary controller, enabling combined linear and rotary motion. This simplifies more advanced tasks—such as gear cutting—without requiring any G-code knowledge beyond the simple keypad inputs.

Included with the Linear Controller:

-

Linear Controller with Keypad

-

Power Supply

Power Supply Specifications:

The included power supply is compatible with 110–240 VAC and automatically adjusts to local voltage, making it suitable for use worldwide. (Earlier versions of this product included a 110 VAC-only power supply.)

Mill Collet Set

Sherline milling collets are specifically designed for use with the Morse #1 internal taper, which is standard on both the Sherline lathe and vertical mill. Due to the shallow angle of the Morse #1 taper, tightening the drawbolt results in significantly greater clamping force compared to WW collets. For this reason, we recommend using these milling collets to securely hold miniature end mills (with 3/16" or 1/4" shanks), #1 and smaller center drills, Dremel® bits (1/8" shank), and a variety of other small cutters.

Inch Mill Collet Set: 1/8", 3/16", 1/4"

Metric Mill Collet Set: 3 mm, 4 mm, 6 mm

Note: Tools held in these collets must have a shank diameter within .001" of the stated size. Because of the shallow taper, the collet will remain tight in the spindle even after loosening the drawbolt. To release it, back the drawbolt out a few turns and tap it lightly to free the collet.

⚠️ CAUTION: When tightening the collet drawbolt with a Tommy bar, be careful not to insert the bar too far into the spindle. Doing so can damage the collet’s taper area. The red arrow in the image below shows an example of this type of damage.

Mill Cutter Arbors

Sherline MB Vise Fixture

The Sherline MB Vise Fixture is designed to locate directly in the T-slots of our mill tables and tooling plates. By aligning the fixed and movable jaws in the T-slots, your mill table or tooling plate becomes the base for the fixture—maximizing usable table length. This setup allows you to securely hold and machine much larger or irregularly shaped parts than traditional vises can accommodate.

Workholding Versatility

The MB Vise Fixture supports a wide range of part shapes through the use of two different sets of interchangeable top jaws:

For square and rectangular stock use the standard top jaws with either:

-

Talon Grip Vise Jaw Inserts (P/N 35526) by Mitee-Bite

-

Reversible Jaw Inserts (P/N 35524) (smooth/serrated) by Saunders

For round or irregularly shaped material:

Use the MB Versagrip Top Jaws (P/N 35535), which fit the same fixed and movable base plates. These jaws accept the MB Versagrip Vise Jaw Inserts (P/N 35529) by Mitee-Bite. The ¾" round inserts can be rotated within any insert pocket to match and grip a wide variety of part geometries securely.

Standard MB Vise Fixture Includes:

-

Fixed base plate

-

Movable base plate

-

Adjustable stop

-

3 hex keys (7/32", 5/32", 3/32")

-

Mounting screws and T-nuts

Insert Options:

-

P/N 35524 – Reversible Jaw Inserts:

One side is serrated for gripping raw stock, and the other is smooth for holding finished parts with minimal marking. Easily reversible in the top jaw (includes 1 insert and 4 screws). -

P/N 35526 – Talon Grip Vise Jaw Inserts:

Double-sided serrated inserts for aggressive holding of raw stock. The serrated edge enhances grip strength (includes 2 inserts and 2 screws). -

P/Ns 35535 & 35529 – MB Versagrip Vise Jaws & Inserts:

Serrated on both sides for secure gripping of raw or irregular material. Compatible only with the Versagrip jaws (includes 4 inserts and 4 screws). -

P/N 35528 – MB Hard Stop:

Designed to fit in the fixed jaw insert slot and used alongside the Talon Grip Inserts (P/N 35526) for repeatable part positioning.

Notes:

-

Jaw inserts are sold separately. The Standard MB Vise Fixture Base Plates are required to mount any jaw inserts.

-

Although the serrated inserts are intended for raw stock, they may be used on finished surfaces if light clamping pressure is applied and only light machining or engraving is performed.

Super-Lube Multi-Purpose Synthetic Grease 3oz

This grease contains PTFE (Teflon) and serves as a clear, non-toxic, multi-purpose lubricant. Super Lube is an NLGI grade 2, heavy-duty lubricant compatible with most other greases. It provides superior adhesion and outlasts conventional lubricants by 40–100%.

Super Lube is dielectric, water-resistant, non-staining, and classified as a USDA H-1 food-grade lubricant. It performs reliably across a broad temperature range of –45°F to 450°F and will not run, drip, dry out, melt, separate, or form gummy residues.

Recommended applications include leadscrews, behind handwheels where they contact thrust surfaces, dovetails on lathes and mills, as well as gears, hinges, and bearings.

For Material Safety Data Sheets (MSDS) and additional product information, visit www.super-lube.com.

Super-Lube Dri-Film Aerosol 11oz

This dry spray contains PTFE, with the propellant evaporating quickly to leave behind a thin, dry layer of PTFE (Teflon). It’s ideal for machine slides as it doesn’t attract chips, and can also be used on leadscrews, locks, linkages, cables, pumps, small gears, and garage door chains or screw drives.

For Material Safety Data Sheets (MSDS) and more information, please visit the Super Lube website at www.super-lube.com.

⚠️ Note: This item can only be shipped by UPS Ground and cannot be shipped outside of the continental US

CALIFORNIA PROP 65 WARNING

NIKX-STIKX Metal-Cutting Compound

NIKX-STIKX is a 2.2-ounce solid metal-cutting compound designed to enhance cutting performance. Unlike traditional lubricants, it is a wax-based compound applied directly to cutting tools and saw blades to reduce friction and promote smoother cuts. Its solid form eliminates the mess and spillage associated with liquid coolants.

Ideal for use on drills, end mills, parting tools, and more, NIKX-STIKX helps extend tool life and improve cutting efficiency. It is also a trusted solution used daily in the Sherline manufacturing shop.