90° 30TPI Straight Knurl Pair

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN STRAIGHT TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 30 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 30 SERIES EP WHEEL … Continued

90° 32TPI Straight Knurl Pair

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN STRAIGHT TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 32 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 32 SERIES EP WHEEL DIAMETER … Continued

90° 35TPI Spiral Knurl Pair

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN Right & Left Hand Pair TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 35 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI … Continued

90° 35TPI Straight Knurl Pair

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN STRAIGHT TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 35 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 35 SERIES EP WHEEL … Continued

90° 40TPI Spiral Knurl Pair

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN Right & Left Hand Pair TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 40 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI … Continued

90° 40TPI Straight Knurl Pair

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN STRAIGHT TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 40 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 40 SERIES EP WHEEL … Continued

90° 41TPI Straight Knurl Pair

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN STRAIGHT TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 41 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 41 SERIES EP WHEEL … Continued

90° 47TPI Straight Knurl Pair

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN STRAIGHT TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 47 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 47 SERIES EP WHEEL … Continued

60° Carbide Tool

Left Hand Carbide Tool

About 1/4″ Brazed Tip Carbide Tools Carbide tools have a small piece of tough carbide brazed to the tip of a softer steel shank. These tools are recommended for cutting hard or abrasive materials. Carbide tools can retain their hardness … Continued

Right Hand Carbide Tool

About 1/4″ Brazed Tip Carbide Tools Carbide tools have a small piece of tough carbide brazed to the tip of a softer steel shank. These tools are recommended for cutting hard or abrasive materials. Carbide tools can retain their hardness … Continued

High Speed Steel Boring Tool

Lathe tools, or tool bits as they are sometimes called, are the cutting tools that are used for turning and facing work on the lathe. The most popular lathe tools are those made of high-speed tool steel (HSS). They can … Continued

Left Hand HSS Tool

Lathe tools—often referred to as tool bits—are the primary cutting tools used for turning and facing operations on a lathe. The most common type is made from high-speed steel (HSS), which is suitable for machining a wide range of materials, including wood, plastic, aluminum, brass, and steel. HSS tool blanks are relatively inexpensive and can maintain their hardness at temperatures up to 1000°F (588°C), making proper control of depth of cut, cutting speed, and feed rate essential.

A major advantage of HSS tools is how easily they can be sharpened. They can be shaped and resharpened using a standard aluminum oxide grinding wheel and, once sharpened, will hold their edge for a long time.

NOTE: A lathe tool is named for the direction the chip exits the tool. A right-hand tool has its cutting edge on the left, causing the chip to peel off to the right.

Right Hand HSS Tool

Lathe tools—often referred to as tool bits—are the primary cutting tools used for turning and facing operations on a lathe. The most common type is made from high-speed steel (HSS), which is suitable for machining a wide range of materials, including wood, plastic, aluminum, brass, and steel. HSS tool blanks are relatively inexpensive and can maintain their hardness at temperatures up to 1000°F (588°C), making proper control of depth of cut, cutting speed, and feed rate essential.

A major advantage of HSS tools is how easily they can be sharpened. They can be shaped and resharpened using a standard aluminum oxide grinding wheel and, once sharpened, will hold their edge for a long time.

NOTE: A lathe tool is named for the direction the chip exits the tool. A right-hand tool has its cutting edge on the left, causing the chip to peel off to the right.

90° 30TPI Left Hand Spiral Knurl

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN Left Hand TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 30 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 30 WHEEL DIAMETER 3/16″ … Continued

90° 30TPI Right Hand Spiral Knurl

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN Right Hand TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 30 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 30 WHEEL DIAMETER 3/16″ … Continued

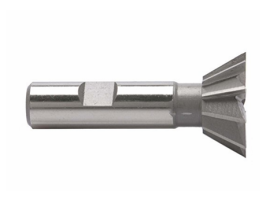

T-Slot Cutter (Carbide, 3/8″ Shank)

T-slot nominal dimensions****Note: The T-slots are extruded into the material. Table surfaces are machined for flatness, but the slots themselves require no additional finishing processes. Slot width, top: .25″ T width, bottom: .40″ Upper slot depth: .10″ T Slot depth: … Continued